How to Create a Shipping Container Office

Friday 28 February 2020

Updated: Thursday 28 May 2020

Filed in: General

The design

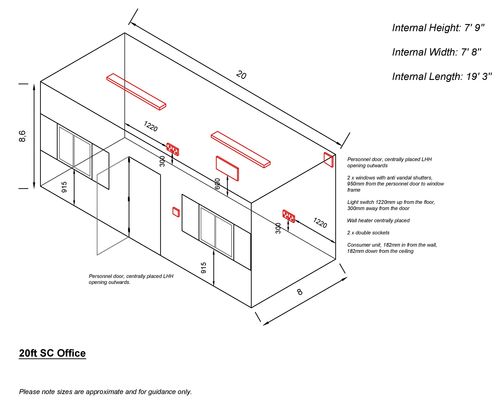

All projects start with good planning. Your input in the design process is the most valuable step, to ensure you get exactly what you need. We use Computer Aided Design to create a picture of the finished structure. At this stage you will let us know exactly what you need, and where you need it. Once you are happy with the design we can begin work. To make things easier we have our ModiBox® range of container offices. These are simple packages to give you a basic office design and also save on the costs of opting for a bespoke design. The ModiBox® range comes in sizes starting at 10ft, and going up to 40ft. Choose from a used shipping container or a new shipping container, to suit your budget. We include a standard package of:- Personnel doors

- Anti-vandal windows

- Exterior repaint

- Melamine lining

- Vinyl flooring

- Electrics

- Partitions

- Patio doors and UVPC windows

- Sky lights

- Canteen packages

- Wood cladding

Planning permission

In some cases you may not need Planning Permission, particularly if the structure is an addition to existing premises, as shipping containers are classed as temporary structures. However, we always recommend checking out beforehand. Contact your local authority before we start work on your container office, to avoid a costly mistake. Often planning permission can be granted, particularly if you are planning to site it in a rural location or a Greenfield site, by having the container clad. This helps it to blend in with the surroundings and disguises the fact it's a metal box. See our article on cladded shipping containers to learn about the different types of wood cladding available and how to clad a container.Doors and windows

Our experienced welders cut apertures for the doors and windows into the container with a welding gun. They will be positioned in accordance with the CAD, which our client will have chosen. The apertures are reinforced with steel box section, so the strength of the container is not compromised. The glazing will be set into the windows during the "fixtures and fittings" stage. Personnel doors are used as standard on container offices, while upgrades include patio style doors, bifolding door, and sliding doors.

Our experienced welders cut apertures for the doors and windows into the container with a welding gun. They will be positioned in accordance with the CAD, which our client will have chosen. The apertures are reinforced with steel box section, so the strength of the container is not compromised. The glazing will be set into the windows during the "fixtures and fittings" stage. Personnel doors are used as standard on container offices, while upgrades include patio style doors, bifolding door, and sliding doors.Repainting

If you have chosen a used container for your container office, it is likely you'll want it repainted, as this considerably improves the appearance of the container. Not only this, but it will prolong its life by providing a weatherproof coating. We use rubberised marine paint. First the container surfaces must be primed for repainting, which includes washing down, repairing any rust spots with either a welded patch or sanding. The paint is administered by means of a spray gun. If you're having a new shipping container its cosmetic appearance will look good enough not to require repainting, but you may want it repainted if you have a particular colour in mind, and to ensure that a uniform colour match after the doors, windows and shutters have been fitted.

If you have chosen a used container for your container office, it is likely you'll want it repainted, as this considerably improves the appearance of the container. Not only this, but it will prolong its life by providing a weatherproof coating. We use rubberised marine paint. First the container surfaces must be primed for repainting, which includes washing down, repairing any rust spots with either a welded patch or sanding. The paint is administered by means of a spray gun. If you're having a new shipping container its cosmetic appearance will look good enough not to require repainting, but you may want it repainted if you have a particular colour in mind, and to ensure that a uniform colour match after the doors, windows and shutters have been fitted.Lining

Any container which is to be inhabited ideally needs insulation, for comfort, and to stop the condensation that easily forms on metal walls. We use 8mm melamine board over a 50mm frame and 100mm rockwall insulation for our container offices, although ply lining is another option. We fit lining and insulation without drilling into the container walls.

Any container which is to be inhabited ideally needs insulation, for comfort, and to stop the condensation that easily forms on metal walls. We use 8mm melamine board over a 50mm frame and 100mm rockwall insulation for our container offices, although ply lining is another option. We fit lining and insulation without drilling into the container walls.Flooring

The original marine ply floor of a shipping container is left intact as it extremely hard wearing, but for cosmetic and hygiene reasons, we lay a heavy duty 2mm, slip and slip resistant vinyl flooring.

The original marine ply floor of a shipping container is left intact as it extremely hard wearing, but for cosmetic and hygiene reasons, we lay a heavy duty 2mm, slip and slip resistant vinyl flooring.Fixtures and fittings

This includes the wiring for the electrics, which is carried out by our qualified electricians. We use CE compliant parts, a four way steel consumer unit and an external hook up. All wiring is surface mounted in plastic conduit and again we avoid drilling into the container by fitting this directly to the lining. If you have a bespoke conversion, for instance the addition of a canteen package, this will be fitted now too.

This includes the wiring for the electrics, which is carried out by our qualified electricians. We use CE compliant parts, a four way steel consumer unit and an external hook up. All wiring is surface mounted in plastic conduit and again we avoid drilling into the container by fitting this directly to the lining. If you have a bespoke conversion, for instance the addition of a canteen package, this will be fitted now too.Delivery

You'll need to prepare your site for the delivery of your shipping container office by making sure the location is accessible to an artic lorry with a hiab crane. The size of these means that you have to think about access, in terms of both road width and height of any overhanging obstacles beforehand. The ground leading up to your site must be hard-standing too, or the lorry could get stuck! It's important that if you have any concerns over potential access issues you discuss it with the conversion team beforehand. It is recommended that you prepare your ground for delivery by making sure the ground where you'll be siting the container is properly prepared. The foundation should either be a concrete base, or four wooden supports in the ground (railway sleepers are good for this). As long as all four corners of the container are supported then no other special preparation is required.

We have placed cookies on your browsing device to enable this website to function correctly.

Further usage of this website indicates you are happy for us to do this..

Find out about the cookies we have set and how we use them.

Further usage of this website indicates you are happy for us to do this..

Find out about the cookies we have set and how we use them.